Brazed Plate Heat Exchanger Piping Diagram

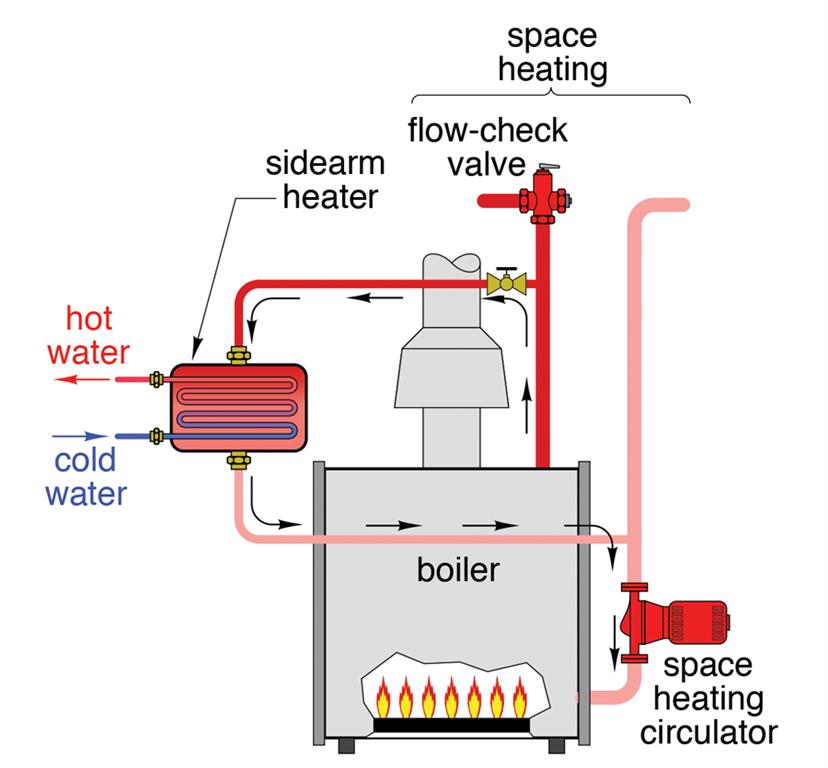

This facilitates the transfer of heat and greatly increases the speed of the temperature change.

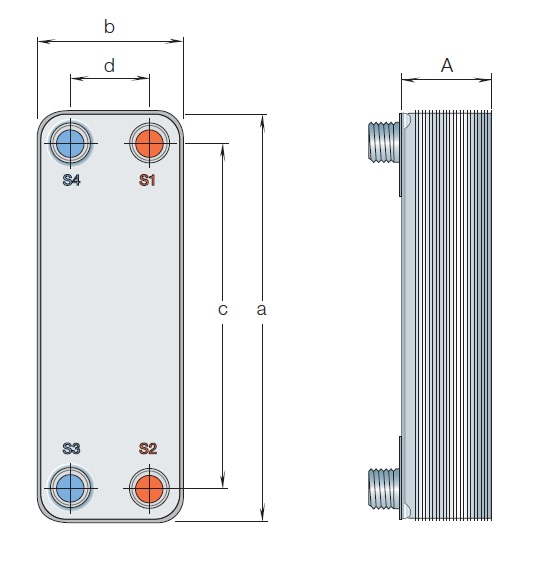

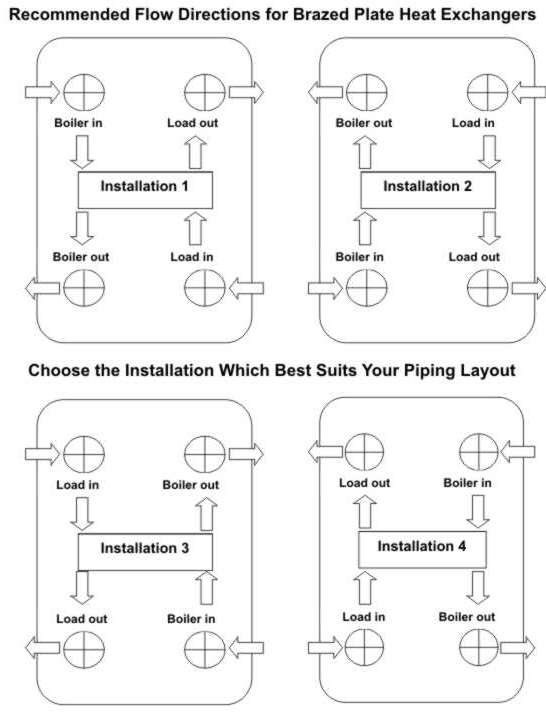

Brazed plate heat exchanger piping diagram. Piping is elevated similar to shell tube exchanger. In this video we ll be looking at the different types of plate heat exchangers to understand ho. Rather than using an adjustable design with replaceable plates like the wesplate these brazed plate heat exchangers cannot be modified so correctly sizing a unit is very important. A flat plate heat exchanger uses a metal heat exchanger plate between the two fluids to achieve a higher overall heat transfer coefficient than either a shell and tube heat exchanger or a.

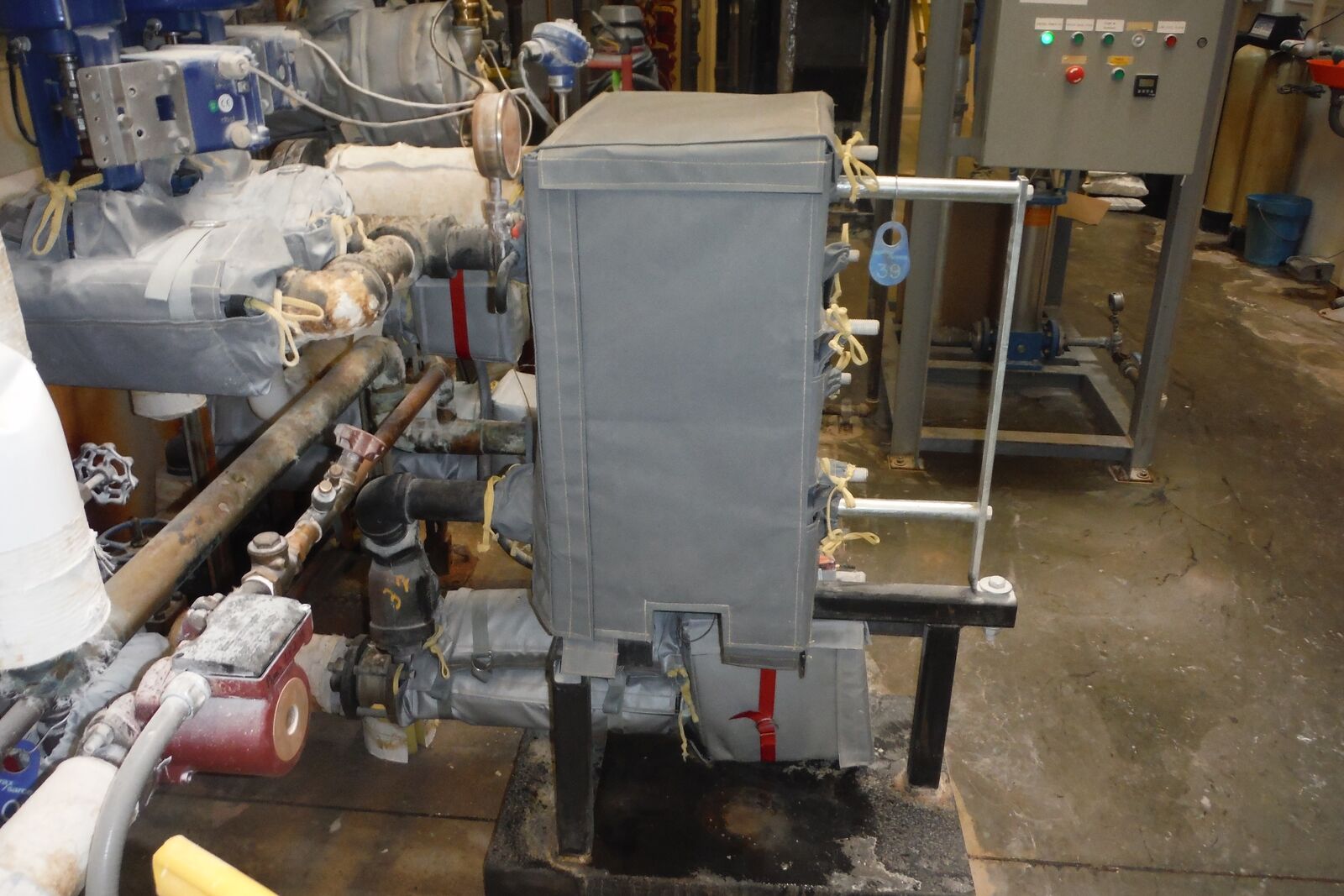

Piping attached to cover plate nozzles of the spiral units is furnished with break flanges. The flat plate heat exchanger also simply called a plate heat exchanger or a plate and frame heat exchanger has both advantages and disadvantages compared to the widely shell and tube heat exchangers. The internals of heat exchangers requires periodic cleaning and repair. Fortunately wessels has produced a few easy to use charts for sizing wespac brazed plate heat exchangers based on use case scenarios like radiant floor.

Figures 22 to 29 indicates various piping configurations for heat exchangers. The piping are to be well supported so that no loads are transferred to the bphe during operation. Medium is thus surrounded by the cold medium to prevent heat loss. Instruction manual for brazed plate heat exchangers f1 f2 f1 f2 f1 f2 f3 f3 f4f3 f1 f2 f3 f4 f4 f4 f5 f5 f6 f6 h h h h l l l l d650 f1 f2 f6 f3 f5 f1 f2 f6.